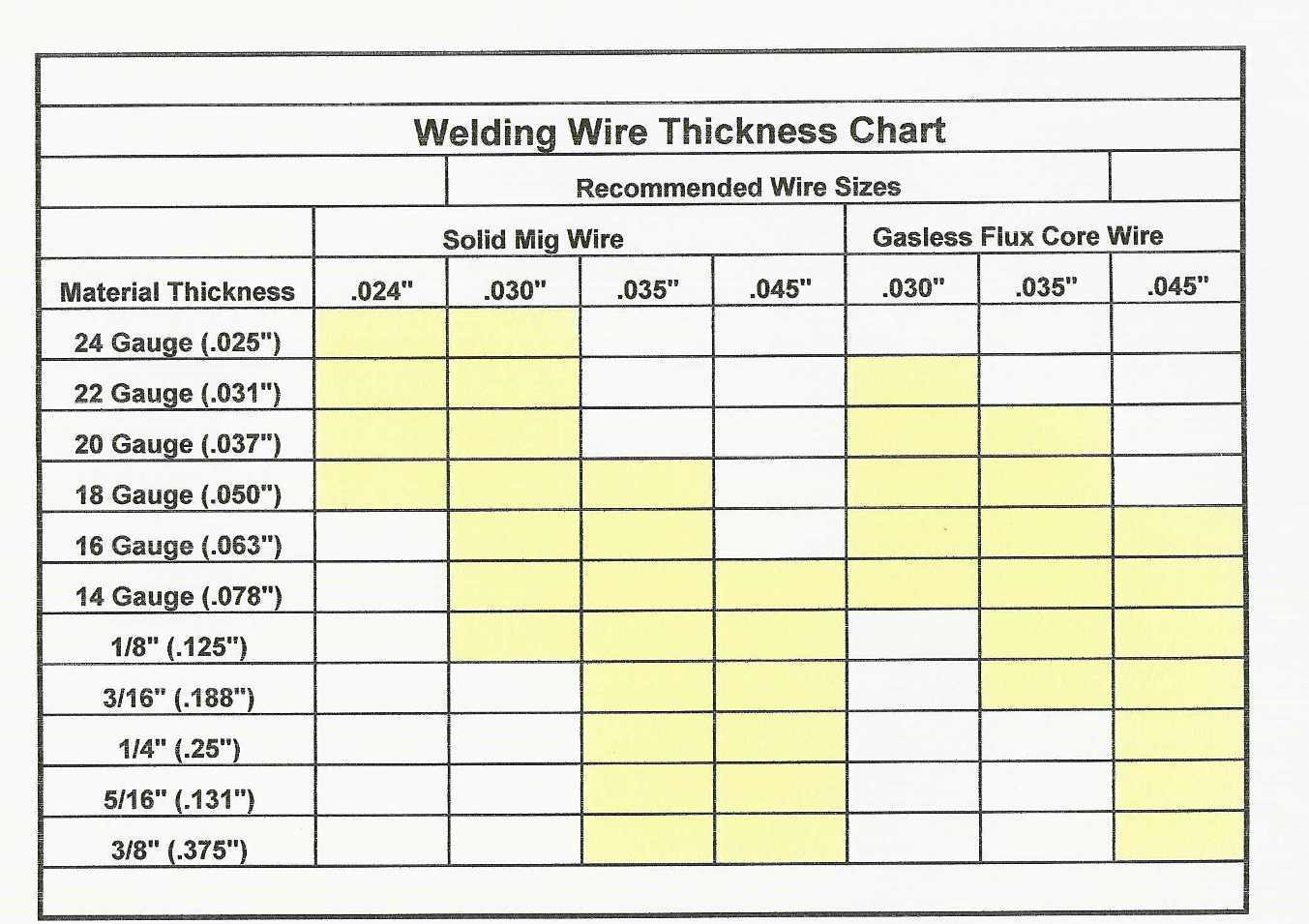

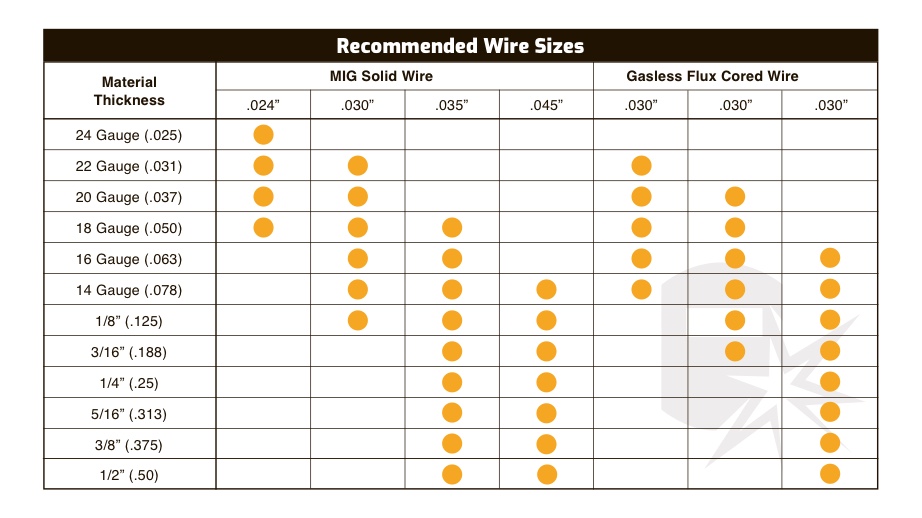

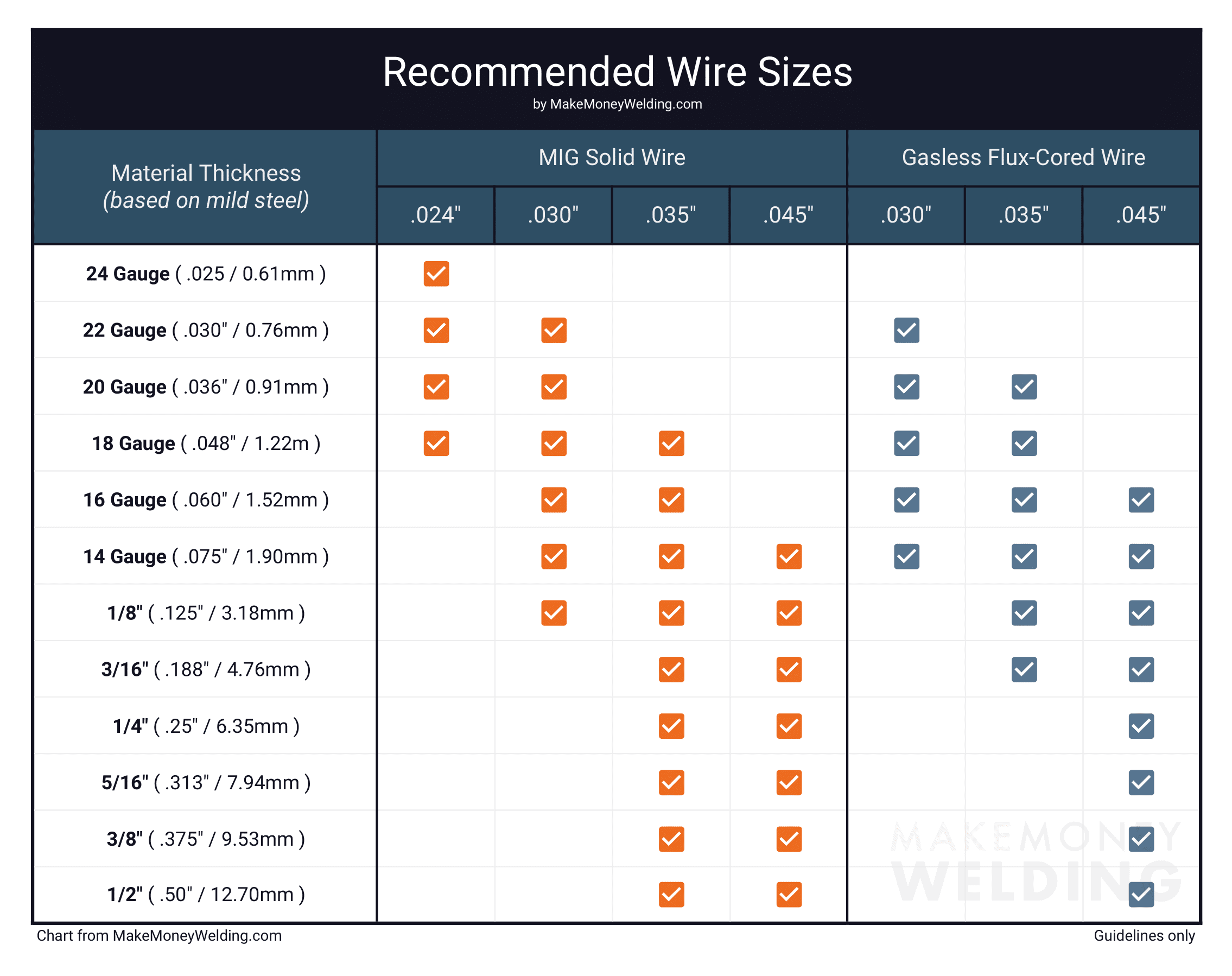

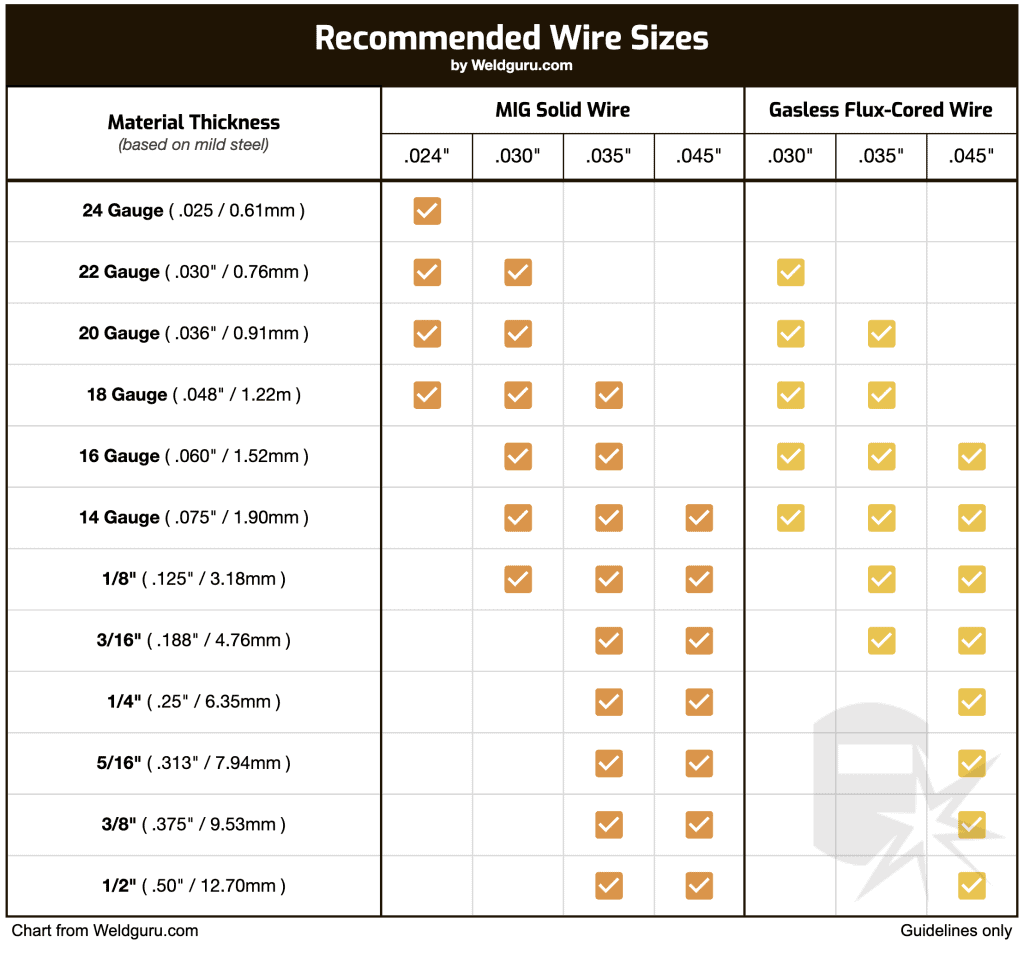

Mig Welding Wire Size Chart

Mig Welding Wire Size Chart - Mig welding, also known as gas metal arc welding (gmaw), is a popular welding process used in various industries. This article explains the basics of the mig welding process, when to apply it, the necessary equipment, gmaw career opportunities, and the pros and cons of mig welding. During mig welding, an electric arc is formed between a wire electrode. In this article, you’ll learn about mig welding details, how it works, different types, setup steps, factors affecting quality, common issues, care tips, applications, when to switch. Mig welding, or metal inert gas welding, is a type of welding that uses wire and gas to form a metal bond. Mig (metal inert gas) welding is an arc welding procedure that utilizes an incessant solid cable electrode heated by a welding gun and fed into the weld pool. It involves using a consumable wire electrode and a. Mig welding (gmaw) is a gas shielding metal arc process that uses the heat of continuously feeding an electric arc between the consumable electrode wire and the base metal. This is a list of aircraft produced by russian aircraft corporation mig, formerly mikoyan, a russian aircraft manufacturer. Mig (metal inert gas) welding is an arc welding procedure that utilizes an incessant solid cable electrode heated by a welding gun and fed into the weld pool. Mig welding, also known as gas metal arc welding (gmaw), is a popular welding process used in various industries. During mig welding, an electric arc is formed between a wire electrode. This is a list of aircraft produced by russian aircraft corporation mig, formerly mikoyan, a russian aircraft manufacturer. It involves using a consumable wire electrode and a. Mig welding (gmaw) is a gas shielding metal arc process that uses the heat of continuously feeding an electric arc between the consumable electrode wire and the base metal. In this article, you’ll learn about mig welding details, how it works, different types, setup steps, factors affecting quality, common issues, care tips, applications, when to switch. Mig welding, or metal inert gas welding, is a type of welding that uses wire and gas to form a metal bond. This article explains the basics of the mig welding process, when to apply it, the necessary equipment, gmaw career opportunities, and the pros and cons of mig welding. This is a list of aircraft produced by russian aircraft corporation mig, formerly mikoyan, a russian aircraft manufacturer. Mig welding, or metal inert gas welding, is a type of welding that uses wire and gas to form a metal bond. Mig welding (gmaw) is a gas shielding metal arc process that uses the heat of continuously feeding an electric arc. This article explains the basics of the mig welding process, when to apply it, the necessary equipment, gmaw career opportunities, and the pros and cons of mig welding. In this article, you’ll learn about mig welding details, how it works, different types, setup steps, factors affecting quality, common issues, care tips, applications, when to switch. Mig (metal inert gas) welding. Mig welding, also known as gas metal arc welding (gmaw), is a popular welding process used in various industries. This article explains the basics of the mig welding process, when to apply it, the necessary equipment, gmaw career opportunities, and the pros and cons of mig welding. It involves using a consumable wire electrode and a. In this article, you’ll. It involves using a consumable wire electrode and a. In this article, you’ll learn about mig welding details, how it works, different types, setup steps, factors affecting quality, common issues, care tips, applications, when to switch. Mig welding, also known as gas metal arc welding (gmaw), is a popular welding process used in various industries. Mig welding, or metal inert. Mig welding, or metal inert gas welding, is a type of welding that uses wire and gas to form a metal bond. In this article, you’ll learn about mig welding details, how it works, different types, setup steps, factors affecting quality, common issues, care tips, applications, when to switch. This article explains the basics of the mig welding process, when. It involves using a consumable wire electrode and a. Mig welding (gmaw) is a gas shielding metal arc process that uses the heat of continuously feeding an electric arc between the consumable electrode wire and the base metal. Mig welding, also known as gas metal arc welding (gmaw), is a popular welding process used in various industries. During mig welding,. It involves using a consumable wire electrode and a. Mig welding, also known as gas metal arc welding (gmaw), is a popular welding process used in various industries. This is a list of aircraft produced by russian aircraft corporation mig, formerly mikoyan, a russian aircraft manufacturer. In this article, you’ll learn about mig welding details, how it works, different types,. Mig welding (gmaw) is a gas shielding metal arc process that uses the heat of continuously feeding an electric arc between the consumable electrode wire and the base metal. Mig welding, also known as gas metal arc welding (gmaw), is a popular welding process used in various industries. Mig (metal inert gas) welding is an arc welding procedure that utilizes. Mig welding, also known as gas metal arc welding (gmaw), is a popular welding process used in various industries. Mig welding (gmaw) is a gas shielding metal arc process that uses the heat of continuously feeding an electric arc between the consumable electrode wire and the base metal. In this article, you’ll learn about mig welding details, how it works,. In this article, you’ll learn about mig welding details, how it works, different types, setup steps, factors affecting quality, common issues, care tips, applications, when to switch. It involves using a consumable wire electrode and a. Mig (metal inert gas) welding is an arc welding procedure that utilizes an incessant solid cable electrode heated by a welding gun and fed. Mig welding (gmaw) is a gas shielding metal arc process that uses the heat of continuously feeding an electric arc between the consumable electrode wire and the base metal. This is a list of aircraft produced by russian aircraft corporation mig, formerly mikoyan, a russian aircraft manufacturer. Mig (metal inert gas) welding is an arc welding procedure that utilizes an incessant solid cable electrode heated by a welding gun and fed into the weld pool. Mig welding, also known as gas metal arc welding (gmaw), is a popular welding process used in various industries. This article explains the basics of the mig welding process, when to apply it, the necessary equipment, gmaw career opportunities, and the pros and cons of mig welding. It involves using a consumable wire electrode and a. During mig welding, an electric arc is formed between a wire electrode.Mig Wire Welding Guide

Flux Core Mig Wire Sizes at Andrew Briones blog

How To MIG Weld Aluminum Beginners Guide (with Chart)

MIG & Flux Core Welding Wire Types & Specification (with Chart) Weld Guru

MIG Welding Wire Essentials A Guide to Types & Uses

Mig Welder Wire Size Chart at Cynthia Heather blog

MIG & Flux Core Welding Wire Types & Specification (with Chart) Weld Guru

MIG Welding Electrodes Wire Selection, Charts Settings And, 53 OFF

Mig Welder Wire Size Chart at Cynthia Heather blog

MIG & Flux Core Welding Wire Types & Specification (with Chart) Weld Guru

In This Article, You’ll Learn About Mig Welding Details, How It Works, Different Types, Setup Steps, Factors Affecting Quality, Common Issues, Care Tips, Applications, When To Switch.

Mig Welding, Or Metal Inert Gas Welding, Is A Type Of Welding That Uses Wire And Gas To Form A Metal Bond.

Related Post: