Flange Bolt Torque Chart

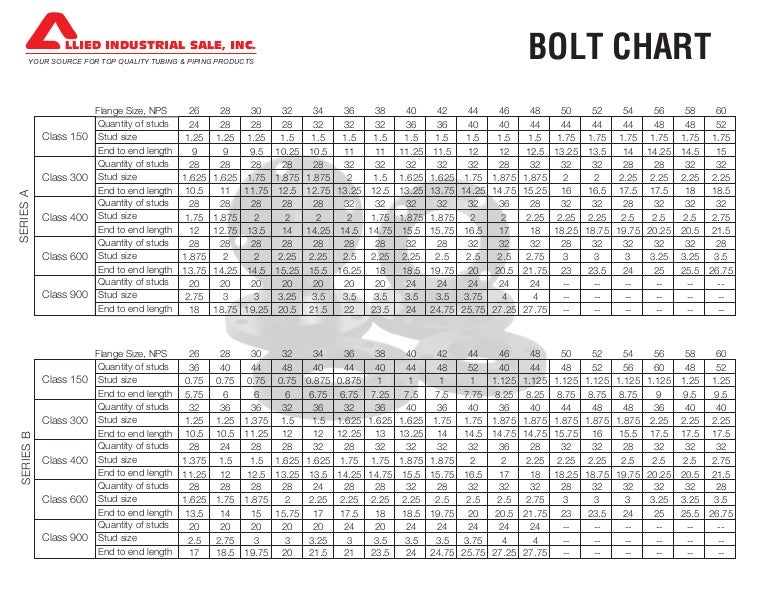

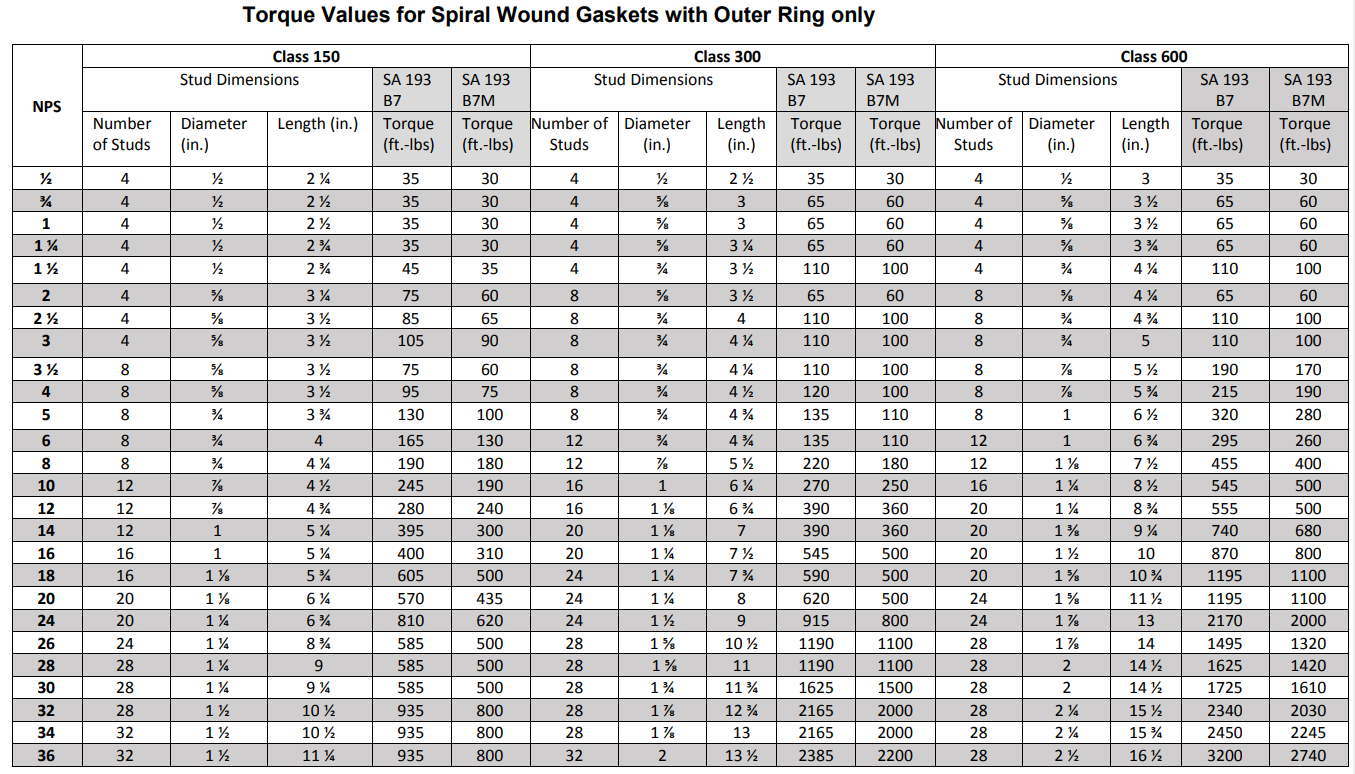

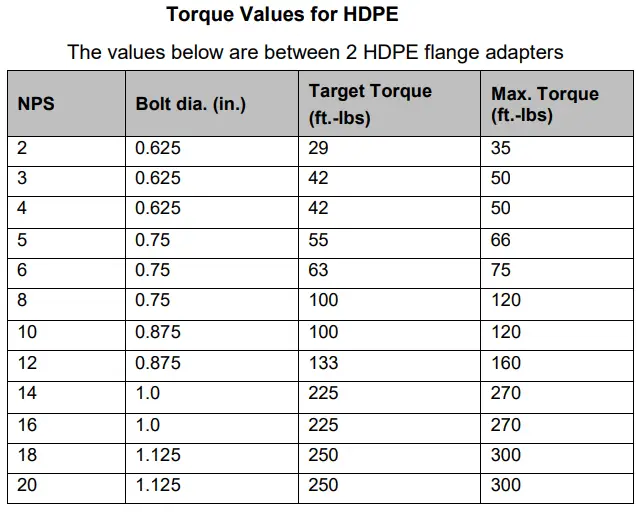

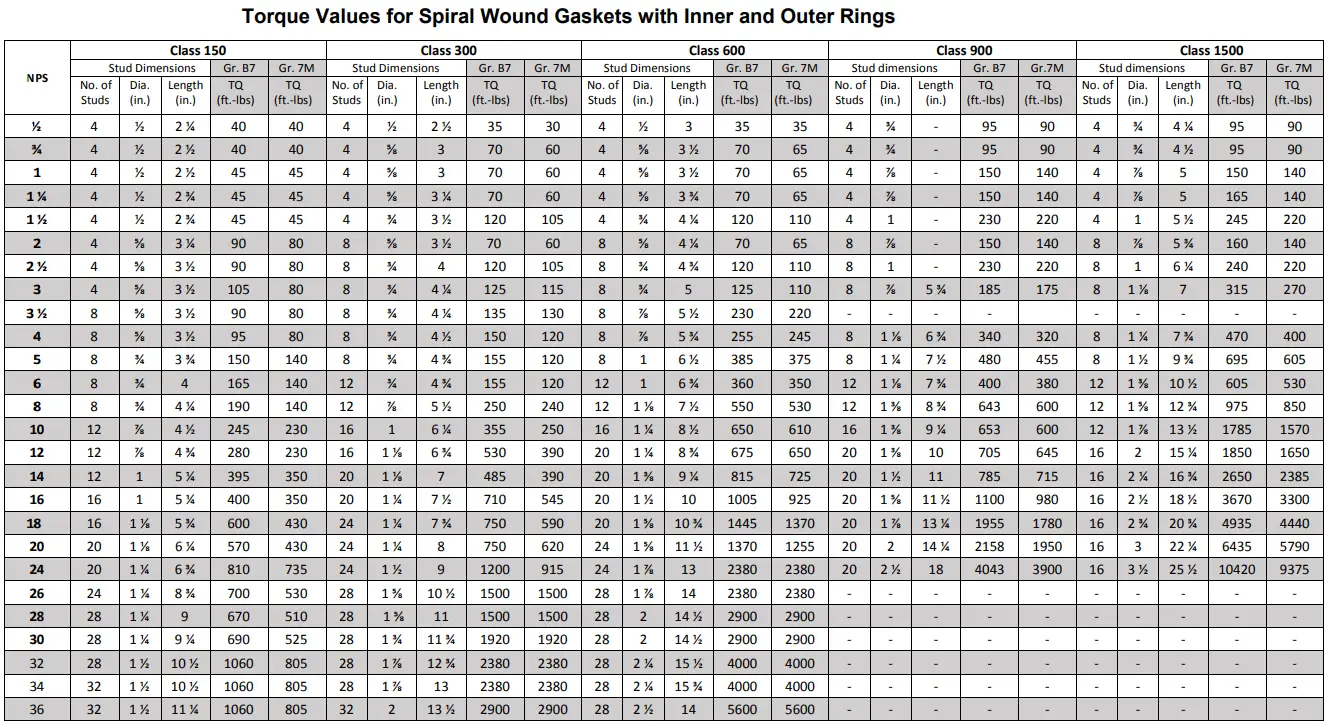

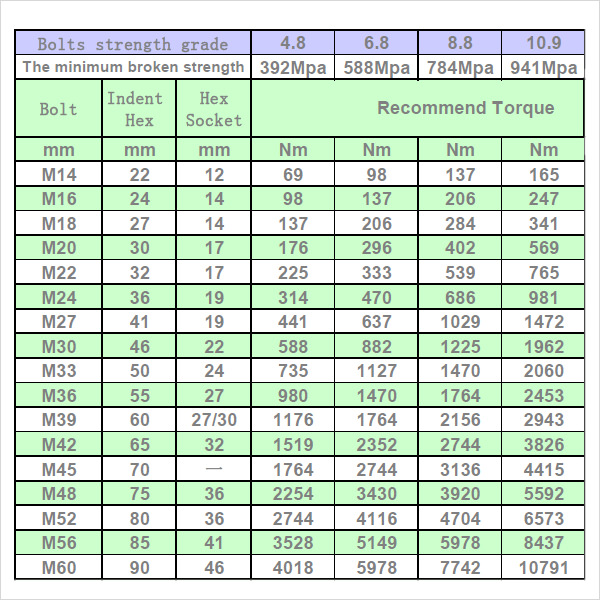

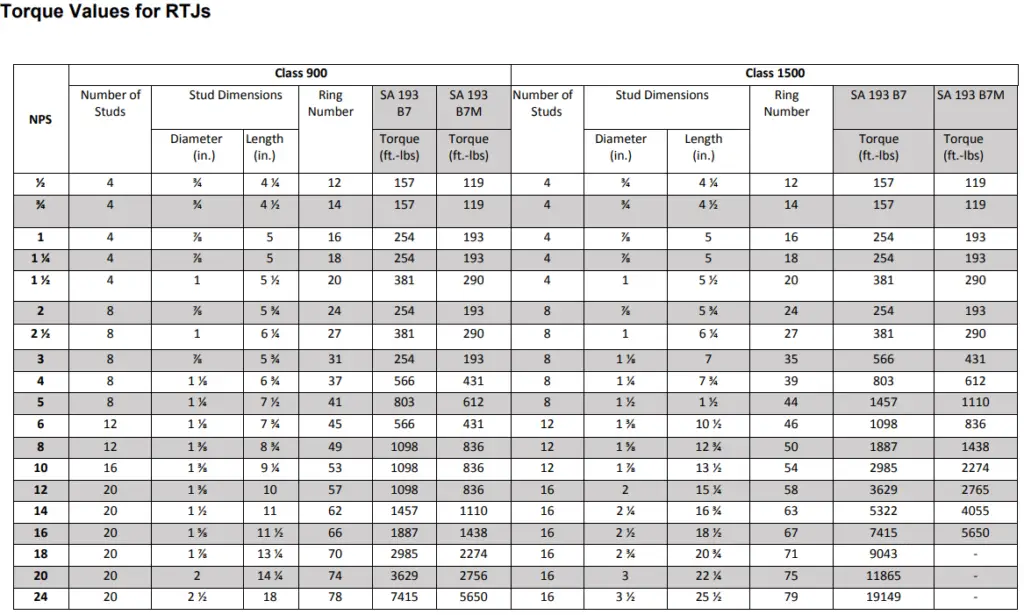

Flange Bolt Torque Chart - Before using a given torque table, these assumptions should be verified to insure they are appropriate for the. Recommended torque values lubricated stud bolts w/0.15 friction value 00# 250. The following charts indicate the approximate bolt torque required to seal flanged joints against internal pressure. In this article, you will learn about the torque sequence of pipe flanges. Torque tables for the installation of flat gaskets with standard asme flanges teadit® material: The torque tables are built on specific assumptions regarding bolt and nut factor. A complete torque tightening sequence with charts for class 150 to 2500 flanges. Asme flange bolting (number, diameter, length of stud bolts by asme flange sizes); Swg class 150 class 300 Stud bolt torque chart (tightening sequence. In this article, we will learn the basics of flange bolt torque calculation and some of the typical torque values in a chart format. Before using a given torque table, these assumptions should be verified to insure they are appropriate for the. Torque is a measure of rotational. The torques given are based on using a 3mm thick 70 irhd rubber gasket. What is flange bolt torque? Learn how to accurately calculate flange bolt torque values and follow the proper tightening sequence to ensure safe and reliable piping connections. The torque tables are built on specific assumptions regarding bolt and nut factor. Look up flange bolt sizes and torque patterns in three taps with flange bolt. A complete torque tightening sequence with charts for class 150 to 2500 flanges. Asme flange bolting (number, diameter, length of stud bolts by asme flange sizes); Before using a given torque table, these assumptions should be verified to insure they are appropriate for the. Just enter the flange size, type, and class, and the tool instantly shows the asme values for: Swg class 150 class 300 Look up flange bolt sizes and torque patterns in three taps with flange bolt. What is flange bolt torque? Key charts for stud bolts: Torque tables for the installation of flat gaskets with standard asme flanges teadit® material: Look up flange bolt sizes and torque patterns in three taps with flange bolt. Es, they are theore s quidelines onl based on using weldneck. What is flange bolt torque? The torques given are based on using a 3mm thick 70 irhd rubber gasket. In this article, we will learn the basics of flange bolt torque calculation and some of the typical torque values in a chart format. Before using a given torque table, these assumptions should be verified to insure they are appropriate for the. Just enter the flange. Asme flange bolting (number, diameter, length of stud bolts by asme flange sizes); Torque is a measure of rotational. Just enter the flange size, type, and class, and the tool instantly shows the asme values for: Torque tables for the installation of flat gaskets with standard asme flanges teadit® material: Look up flange bolt sizes and torque patterns in three. Torque tables for the installation of flat gaskets with standard asme flanges teadit® material: Recommended torque values lubricated stud bolts w/0.15 friction value 00# 250. The torque tables are built on specific assumptions regarding bolt and nut factor. In this article, you will learn about the torque sequence of pipe flanges. Asme flange bolting (number, diameter, length of stud bolts. Recommended torque values lubricated stud bolts w/0.15 friction value 00# 250. Learn how to accurately calculate flange bolt torque values and follow the proper tightening sequence to ensure safe and reliable piping connections. Torque is a measure of rotational. In this article, you will learn about the torque sequence of pipe flanges. Es, they are theore s quidelines onl based. The following charts indicate the approximate bolt torque required to seal flanged joints against internal pressure. Look up flange bolt sizes and torque patterns in three taps with flange bolt. Before using a given torque table, these assumptions should be verified to insure they are appropriate for the. A complete torque tightening sequence with charts for class 150 to 2500. Swg class 150 class 300 A complete torque tightening sequence with charts for class 150 to 2500 flanges. The torques given are based on using a 3mm thick 70 irhd rubber gasket. Asme flange bolting (number, diameter, length of stud bolts by asme flange sizes); In this article, we will learn the basics of flange bolt torque calculation and some. Key charts for stud bolts: Before using a given torque table, these assumptions should be verified to insure they are appropriate for the. Just enter the flange size, type, and class, and the tool instantly shows the asme values for: The torque tables are built on specific assumptions regarding bolt and nut factor. Torque tables for the installation of flat. These bolt torque values are intended for use as guidelines only and are based on ideal conditions, perfect flanges, flange alignment & new well lubricated bolts/nuts according to the. In this article, we will learn the basics of flange bolt torque calculation and some of the typical torque values in a chart format. The torque tables are built on specific. Recommended torque values lubricated stud bolts w/0.15 friction value 00# 250. In this article, we will learn the basics of flange bolt torque calculation and some of the typical torque values in a chart format. Asme flange bolting (number, diameter, length of stud bolts by asme flange sizes); Swg class 150 class 300 In this article, you will learn about the torque sequence of pipe flanges. Learn how to accurately calculate flange bolt torque values and follow the proper tightening sequence to ensure safe and reliable piping connections. Torque tables for the installation of flat gaskets with standard asme flanges teadit® material: Before using a given torque table, these assumptions should be verified to insure they are appropriate for the. Look up flange bolt sizes and torque patterns in three taps with flange bolt. The torque tables are built on specific assumptions regarding bolt and nut factor. Es, they are theore s quidelines onl based on using weldneck. What is flange bolt torque? The following charts indicate the approximate bolt torque required to seal flanged joints against internal pressure. Just enter the flange size, type, and class, and the tool instantly shows the asme values for: A complete torque tightening sequence with charts for class 150 to 2500 flanges. These bolt torque values are intended for use as guidelines only and are based on ideal conditions, perfect flanges, flange alignment & new well lubricated bolts/nuts according to the.Metric Bolt Torque Chart For Flanges

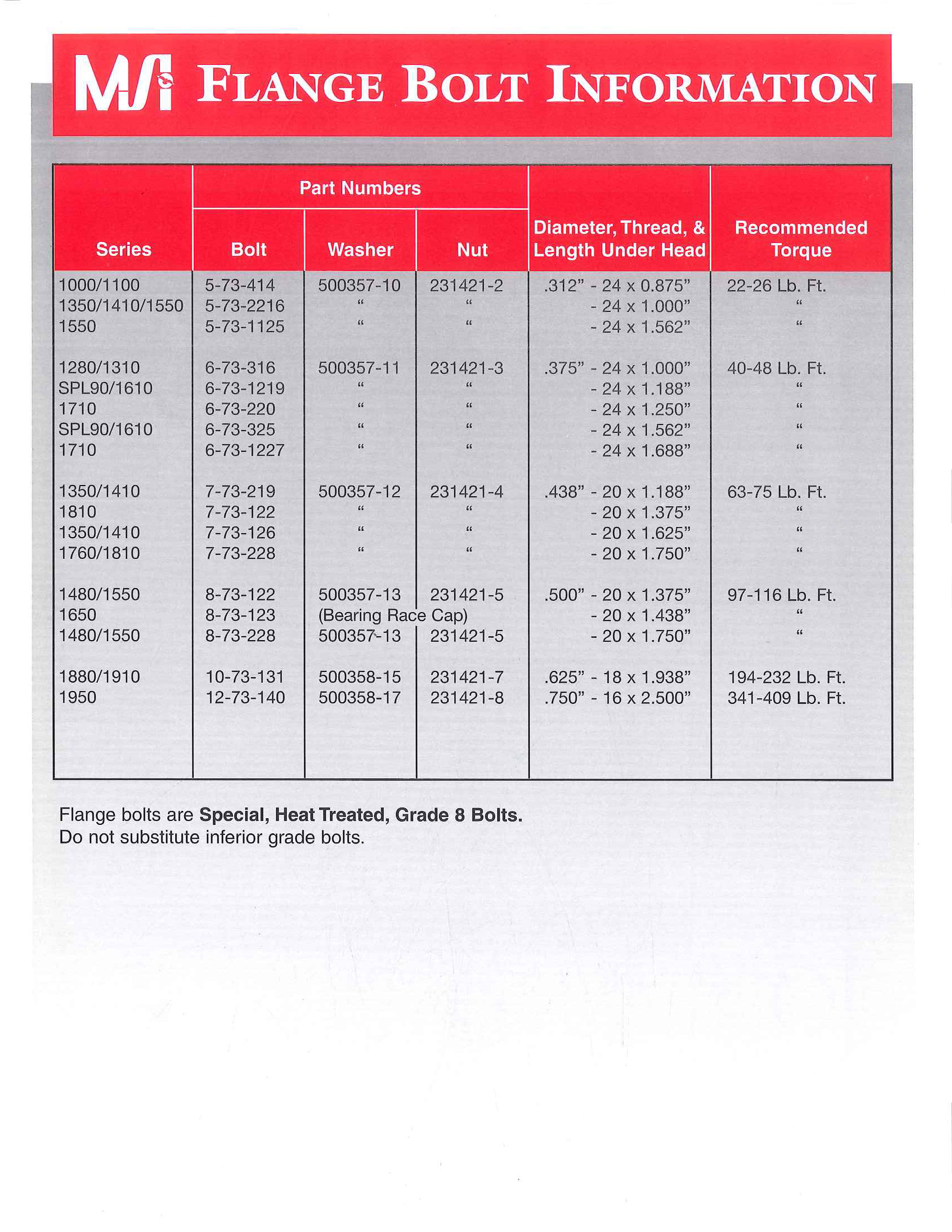

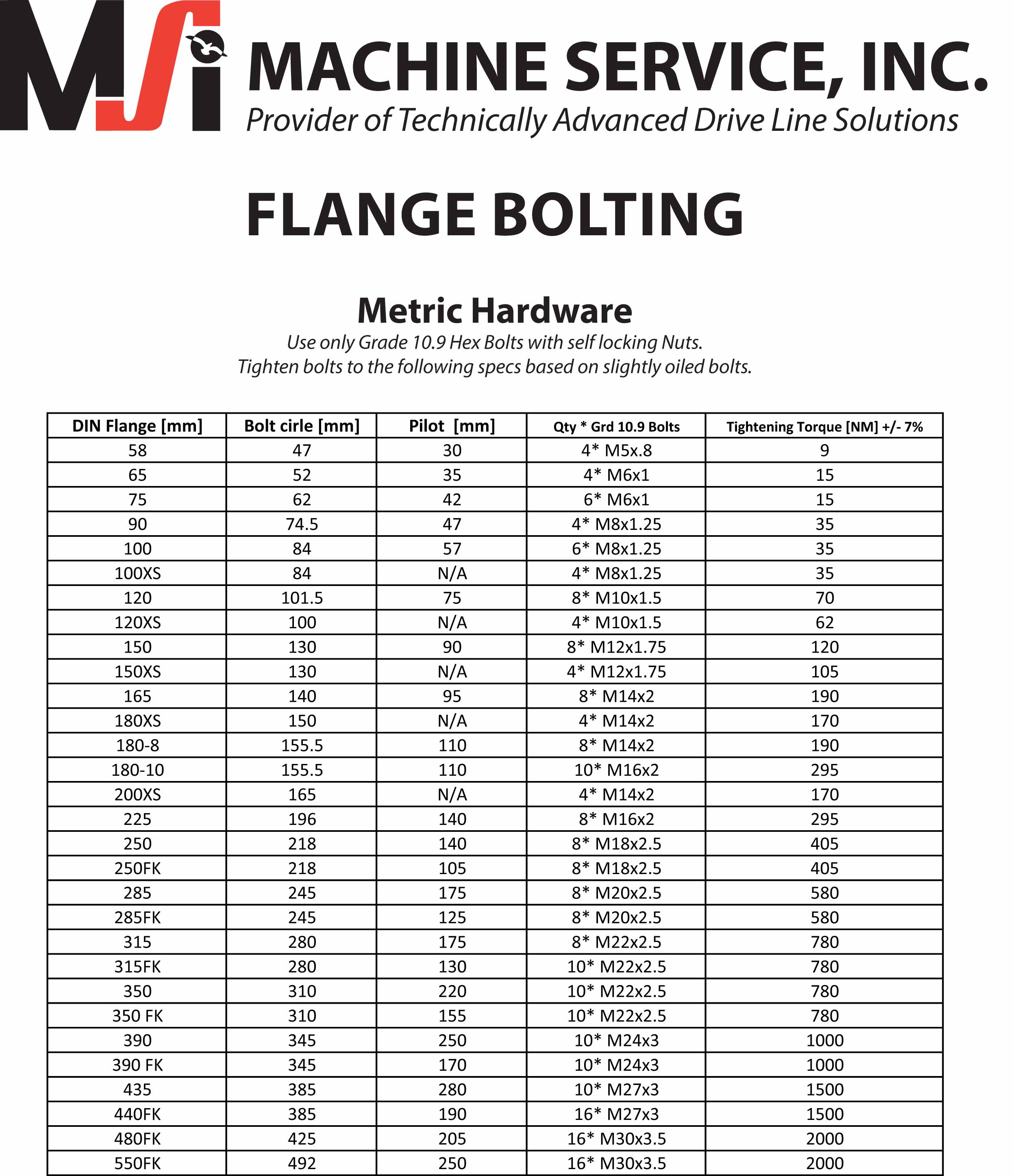

Torque Specifications Machine Service, Inc.

Torque Specifications Machine Service, Inc.

Flange Bolt Torque Calculator at Erik Corbett blog

Flange Bolt Torque Calculation and Pipe Flange Bolt Torque Chart What Is Piping

Flange Bolt Torque Calculation and Pipe Flange Bolt Torque Chart What Is Piping

Flange Bolt Torque Calculation and Pipe Flange Bolt Torque Chart What Is Piping

Ansi Flange Bolt Torque Chart at Rosie Borton blog

Sae Flange Torque Chart

Flange Bolt Torque Calculation and Pipe Flange Bolt Torque Chart What Is Piping

The Torques Given Are Based On Using A 3Mm Thick 70 Irhd Rubber Gasket.

Key Charts For Stud Bolts:

Torque Is A Measure Of Rotational.

Stud Bolt Torque Chart (Tightening Sequence.

Related Post: