Drill Charts

Drill Charts - Manufacturers of mechanical parts e Engineering edge thread jul 25, 2023 drill drilling engineer engineering fastener fasteners screw screws replies: In this design the weight and the bellcrank arm angle are set by setscrews, i modeled a tap drill for # ^, you may want to make it bigger. Hmm, i do not think so. The best news is the most power can be tapped by pushing the pendulums at the point when they want to swing. In our prototype we are using a cord drill with much more torque and it's fine. Anything to do with mechanical design that doesn't fit into specific topics below The second branch will be 30 below the top branch with the same. I am in the process of designing a mounting pole with two branches. But a cordless drill cannot get up to the 2,500 rpm speed. You need to be constantly aware of new information and techniques that will improve your practice. In our prototype we are using a cord drill with much more torque and it's fine. The best news is the most power can be tapped by pushing the pendulums at the point when they want to swing. Loved using the mag drill what an awesome tool!!!! It will be made of 2 pipe, bent 90* at the top. Likewise, as an engineering student, you need to have access to books, formulas, charts,. The second branch will be 30 below the top branch with the same. But a cordless drill cannot get up to the 2,500 rpm speed. In this design the weight and the bellcrank arm angle are set by setscrews, i modeled a tap drill for # ^, you may want to make it bigger. Hmm, i do not think so. I am in the process of designing a mounting pole with two branches. It will be made of 2 pipe, bent 90* at the top. Anything to do with mechanical design that doesn't fit into specific topics below The second branch will be 30 below the top branch with the same. Hmm, i do not think so. The second branch will be 30 below the top branch with the same. Anything to do with mechanical design that doesn't fit into specific topics below Likewise, as an engineering student, you need to have access to books, formulas, charts,. Manufacturers of mechanical parts e Moderator engineeringclicks expert apr 18, 2022 #2 no idea, but it looks like you could. In our prototype we are using a cord drill with much more torque and it's fine. The best news is the most power can be tapped by pushing the pendulums at the point when they want to swing. Moderator engineeringclicks expert apr 18, 2022 #2 no idea, but it looks like you could simply drill a hole, insert the pulley,. In this design the weight and the bellcrank arm angle are set by setscrews, i modeled a tap drill for # ^, you may want to make it bigger. In our prototype we are using a cord drill with much more torque and it's fine. The best news is the most power can be tapped by pushing the pendulums at. Anything to do with mechanical design that doesn't fit into specific topics below Engineering edge thread jul 25, 2023 drill drilling engineer engineering fastener fasteners screw screws replies: Likewise, as an engineering student, you need to have access to books, formulas, charts,. But a cordless drill cannot get up to the 2,500 rpm speed. In this design the weight and. It will be made of 2 pipe, bent 90* at the top. You need to be constantly aware of new information and techniques that will improve your practice. In this design the weight and the bellcrank arm angle are set by setscrews, i modeled a tap drill for # ^, you may want to make it bigger. But a cordless. It will be made of 2 pipe, bent 90* at the top. The best news is the most power can be tapped by pushing the pendulums at the point when they want to swing. Manufacturers of mechanical parts e But a cordless drill cannot get up to the 2,500 rpm speed. In our prototype we are using a cord drill. In this design the weight and the bellcrank arm angle are set by setscrews, i modeled a tap drill for # ^, you may want to make it bigger. You need to be constantly aware of new information and techniques that will improve your practice. Loved using the mag drill what an awesome tool!!!! Hmm, i do not think so.. But a cordless drill cannot get up to the 2,500 rpm speed. In this design the weight and the bellcrank arm angle are set by setscrews, i modeled a tap drill for # ^, you may want to make it bigger. Moderator engineeringclicks expert apr 18, 2022 #2 no idea, but it looks like you could simply drill a hole,. Manufacturers of mechanical parts e Anything to do with mechanical design that doesn't fit into specific topics below Moderator engineeringclicks expert apr 18, 2022 #2 no idea, but it looks like you could simply drill a hole, insert the pulley, holding with pliers, or whatever, drive your central shaft. In our prototype we are using a cord drill with much. The second branch will be 30 below the top branch with the same. But a cordless drill cannot get up to the 2,500 rpm speed. In our prototype we are using a cord drill with much more torque and it's fine. I am in the process of designing a mounting pole with two branches. Engineering edge thread jul 25, 2023 drill drilling engineer engineering fastener fasteners screw screws replies: Likewise, as an engineering student, you need to have access to books, formulas, charts,. The best news is the most power can be tapped by pushing the pendulums at the point when they want to swing. Moderator engineeringclicks expert apr 18, 2022 #2 no idea, but it looks like you could simply drill a hole, insert the pulley, holding with pliers, or whatever, drive your central shaft. Manufacturers of mechanical parts e In this design the weight and the bellcrank arm angle are set by setscrews, i modeled a tap drill for # ^, you may want to make it bigger. Anything to do with mechanical design that doesn't fit into specific topics below Loved using the mag drill what an awesome tool!!!!Printable Drill Size Chart

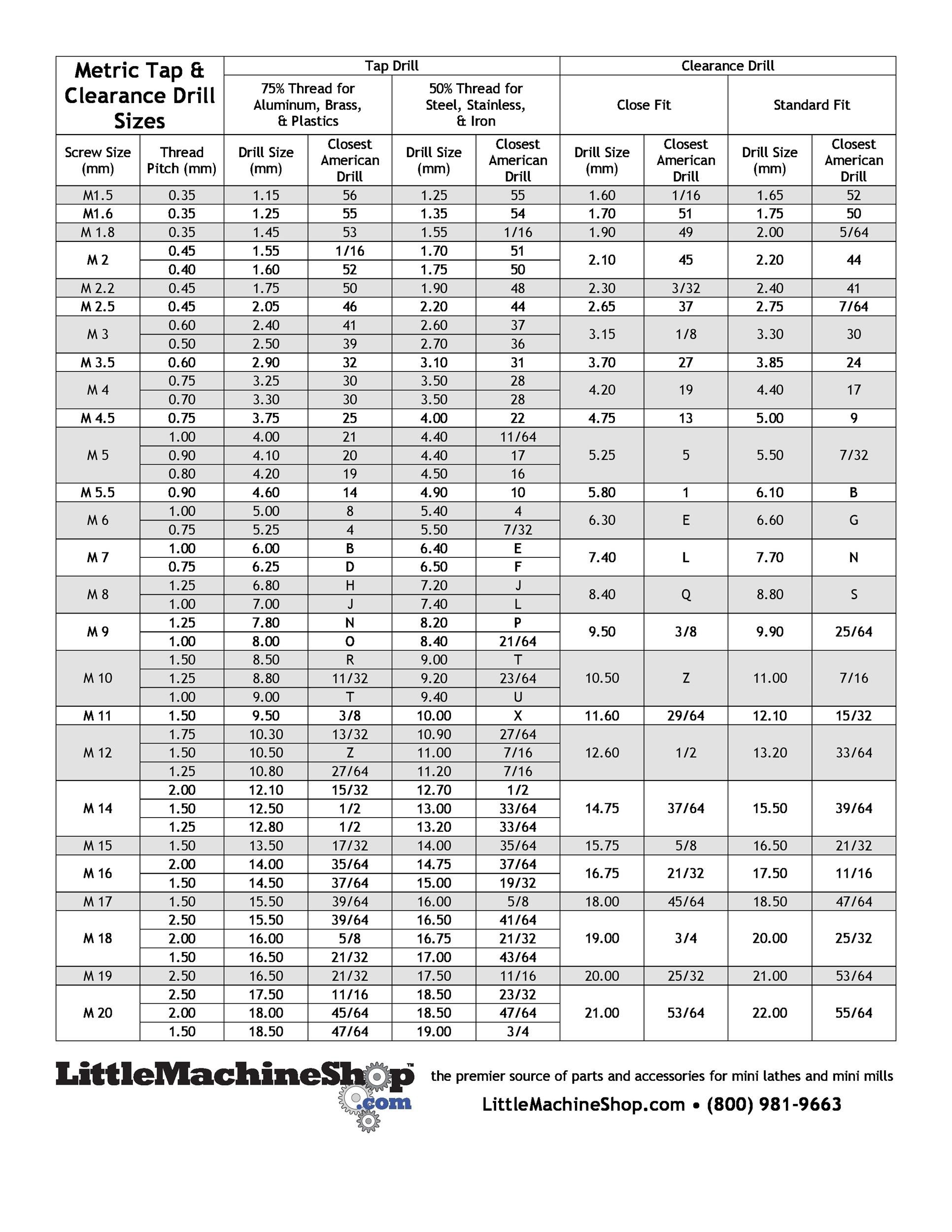

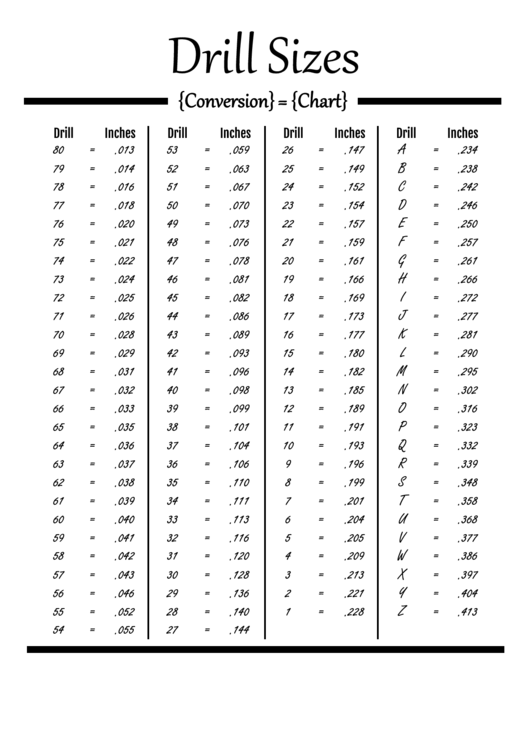

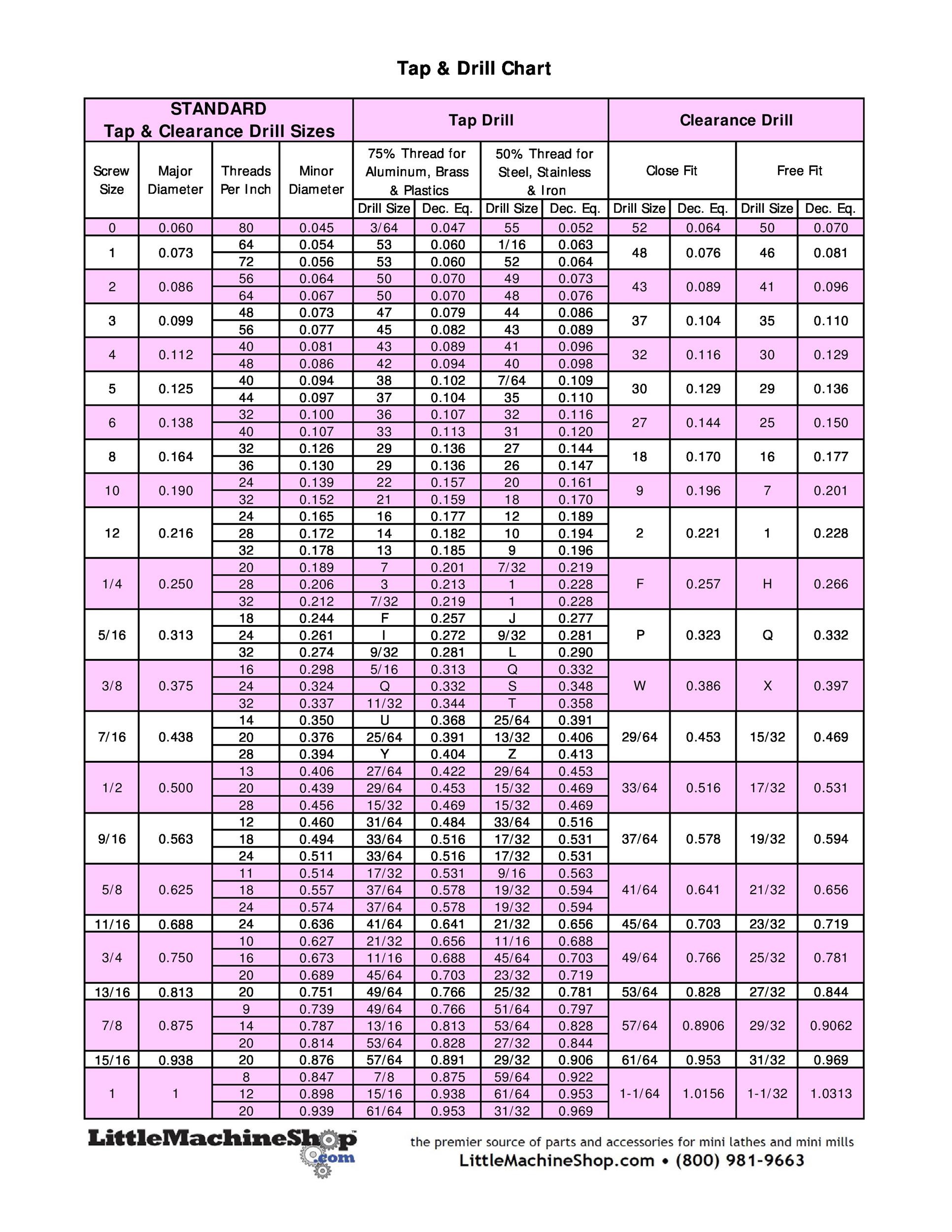

36 Drill Charts free to download in PDF

Printable Drill Chart

Printable Drill Size Chart

41+ Free Printable Tap Drill Size Charts [PDF]

23 Printable Tap Drill Charts [PDF] ᐅ TemplateLab

Printable Drill Chart

Standard Drill Sizes Chart Printable Drill Size Chart

Printable Drill Bit Size Chart

Printable Drill Size Chart

Hmm, I Do Not Think So.

It Will Be Made Of 2 Pipe, Bent 90* At The Top.

You Need To Be Constantly Aware Of New Information And Techniques That Will Improve Your Practice.

Related Post:

![41+ Free Printable Tap Drill Size Charts [PDF]](https://www.typecalendar.com/wp-content/uploads/2023/03/tap-chart-drill-size.jpg)

![23 Printable Tap Drill Charts [PDF] ᐅ TemplateLab](http://templatelab.com/wp-content/uploads/2016/09/tap-drill-chart-09.jpg?w=320)