Buffing Compound Chart

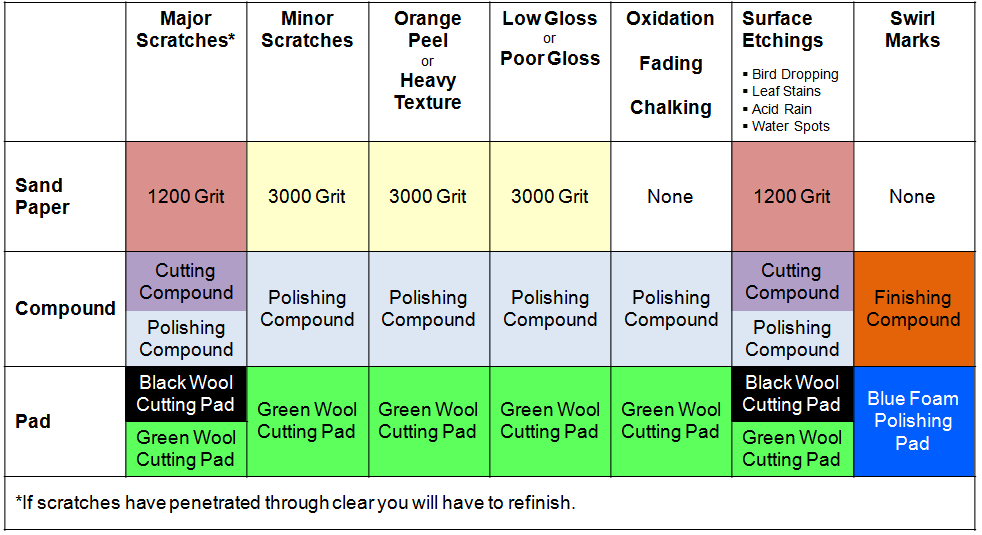

Buffing Compound Chart - The term buffing is a superfinishing process in which there is a buffing wheel (attached with abrasive disc) that is used to remove the bur or unwanted material from the. They both involve smoothing the surface of a workpiece to improve its. They both entail smoothing the surface of a workpiece to improve its appearance as. Buffing and polishing are two common finishing processes used in the manufacturing industry. It does so by evening out nicks and scratches on painted or raw wood, aluminum, copper, glass,. The main difference between buffing and polishing is that buffing removes scratches, marks, and oxidation while polishing creates a glossy, reflective finish using a smoother abrasive. Buffing is a surface treatment process that involves smoothing and polishing of metals to achieve a glossy and refined appearance. Polishing refers to finishing methods that use abrasive belts, whereas buffing refers to finishing methods that use cloth or buffing wheels with polishing compounds. Buffing is the act of smoothing out a surface and giving it a shiny appearance. It levels out the residues or excess products to provide a smooth surface and. It does so by evening out nicks and scratches on painted or raw wood, aluminum, copper, glass,. It utilizes a rotating wheel or pad,. Buffing and polishing are two common finishing processes used in the manufacturing industry. It levels out the residues or excess products to provide a smooth surface and. They both involve smoothing the surface of a workpiece to improve its. The main difference between buffing and polishing is that buffing removes scratches, marks, and oxidation while polishing creates a glossy, reflective finish using a smoother abrasive. Buffing is a surface treatment process that involves smoothing and polishing of metals to achieve a glossy and refined appearance. They both entail smoothing the surface of a workpiece to improve its appearance as. Buffing is a surface finishing process to shine metal, wood, or composites. Polishing refers to finishing methods that use abrasive belts, whereas buffing refers to finishing methods that use cloth or buffing wheels with polishing compounds. It does so by evening out nicks and scratches on painted or raw wood, aluminum, copper, glass,. They both entail smoothing the surface of a workpiece to improve its appearance as. Buffing is a key finishing process used to create smooth, shiny surfaces on metal components. Buffing is a surface treatment process that involves smoothing and polishing of metals to. The main difference between buffing and polishing is that buffing removes scratches, marks, and oxidation while polishing creates a glossy, reflective finish using a smoother abrasive. It levels out the residues or excess products to provide a smooth surface and. Polishing refers to finishing methods that use abrasive belts, whereas buffing refers to finishing methods that use cloth or buffing. Polishing refers to finishing methods that use abrasive belts, whereas buffing refers to finishing methods that use cloth or buffing wheels with polishing compounds. They both involve smoothing the surface of a workpiece to improve its. Buffing is a surface treatment process that involves smoothing and polishing of metals to achieve a glossy and refined appearance. The main difference between. Buffing and polishing are two common finishing processes used in the manufacturing industry. Buffing is a surface treatment process that involves smoothing and polishing of metals to achieve a glossy and refined appearance. It utilizes a rotating wheel or pad,. The term buffing is a superfinishing process in which there is a buffing wheel (attached with abrasive disc) that is. The term buffing is a superfinishing process in which there is a buffing wheel (attached with abrasive disc) that is used to remove the bur or unwanted material from the. They both involve smoothing the surface of a workpiece to improve its. Is polishing the same as buffing? The main difference between buffing and polishing is that buffing removes scratches,. Buffing is a surface finishing process to shine metal, wood, or composites. Buffing and polishing are two common finishing processes used in the manufacturing industry. The term buffing is a superfinishing process in which there is a buffing wheel (attached with abrasive disc) that is used to remove the bur or unwanted material from the. They both entail smoothing the. Buffing is a key finishing process used to create smooth, shiny surfaces on metal components. The main difference between buffing and polishing is that buffing removes scratches, marks, and oxidation while polishing creates a glossy, reflective finish using a smoother abrasive. It utilizes a rotating wheel or pad,. Buffing is a surface finishing process to shine metal, wood, or composites.. They both entail smoothing the surface of a workpiece to improve its appearance as. Buffing is a surface treatment process that involves smoothing and polishing of metals to achieve a glossy and refined appearance. It does so by evening out nicks and scratches on painted or raw wood, aluminum, copper, glass,. It levels out the residues or excess products to. Buffing is a key finishing process used to create smooth, shiny surfaces on metal components. Two often utilized finishing techniques in the production sector are buffing and polishing. In this detailed guide, we will cover the entire buffing finishing process, the tools. Is polishing the same as buffing? They both entail smoothing the surface of a workpiece to improve its. It does so by evening out nicks and scratches on painted or raw wood, aluminum, copper, glass,. In this detailed guide, we will cover the entire buffing finishing process, the tools. Mechanical finishing expert, pat wenino, explains the differences between the two processes. The term buffing is a superfinishing process in which there is a buffing wheel (attached with abrasive. They both involve smoothing the surface of a workpiece to improve its. Buffing is a key finishing process used to create smooth, shiny surfaces on metal components. It does so by evening out nicks and scratches on painted or raw wood, aluminum, copper, glass,. They both entail smoothing the surface of a workpiece to improve its appearance as. Buffing is a surface finishing process to shine metal, wood, or composites. In this detailed guide, we will cover the entire buffing finishing process, the tools. Is polishing the same as buffing? Buffing and polishing are two common finishing processes used in the manufacturing industry. Buffing is a surface treatment process that involves smoothing and polishing of metals to achieve a glossy and refined appearance. Mechanical finishing expert, pat wenino, explains the differences between the two processes. Two often utilized finishing techniques in the production sector are buffing and polishing. It levels out the residues or excess products to provide a smooth surface and. Polishing refers to finishing methods that use abrasive belts, whereas buffing refers to finishing methods that use cloth or buffing wheels with polishing compounds.What Do The Different Colors Of Buffing Compound Mean at Barbara Feagin blog

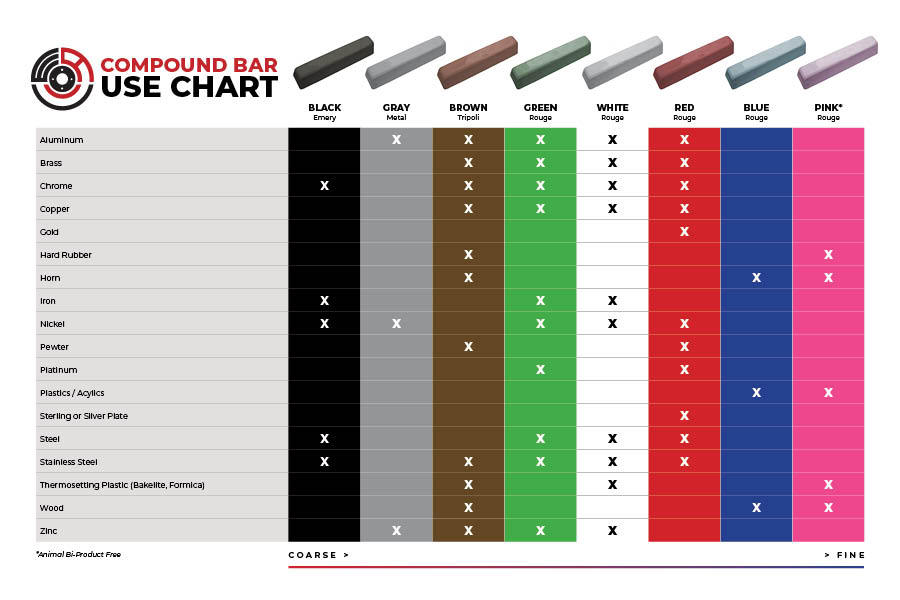

buffing compound color chart PURUI Polishing Products

Buffing Compound Color Chart Metal working tools, Metal fabrication tools, Knife making

Buffing Compound Color Chart PURUI Polishing Products

Buffing Compound Chart Portal.posgradount.edu.pe

Buffing Wheel Color Chart at Jason Brook blog

Buffing Compounds Empire Abrasives

BUFFING WHEELS AND BUFFING COMPOUNDS EXPLAINED Maverick Abrasives

Buffing Wheel Compound Selection Chart A Visual Reference of Charts Chart Master

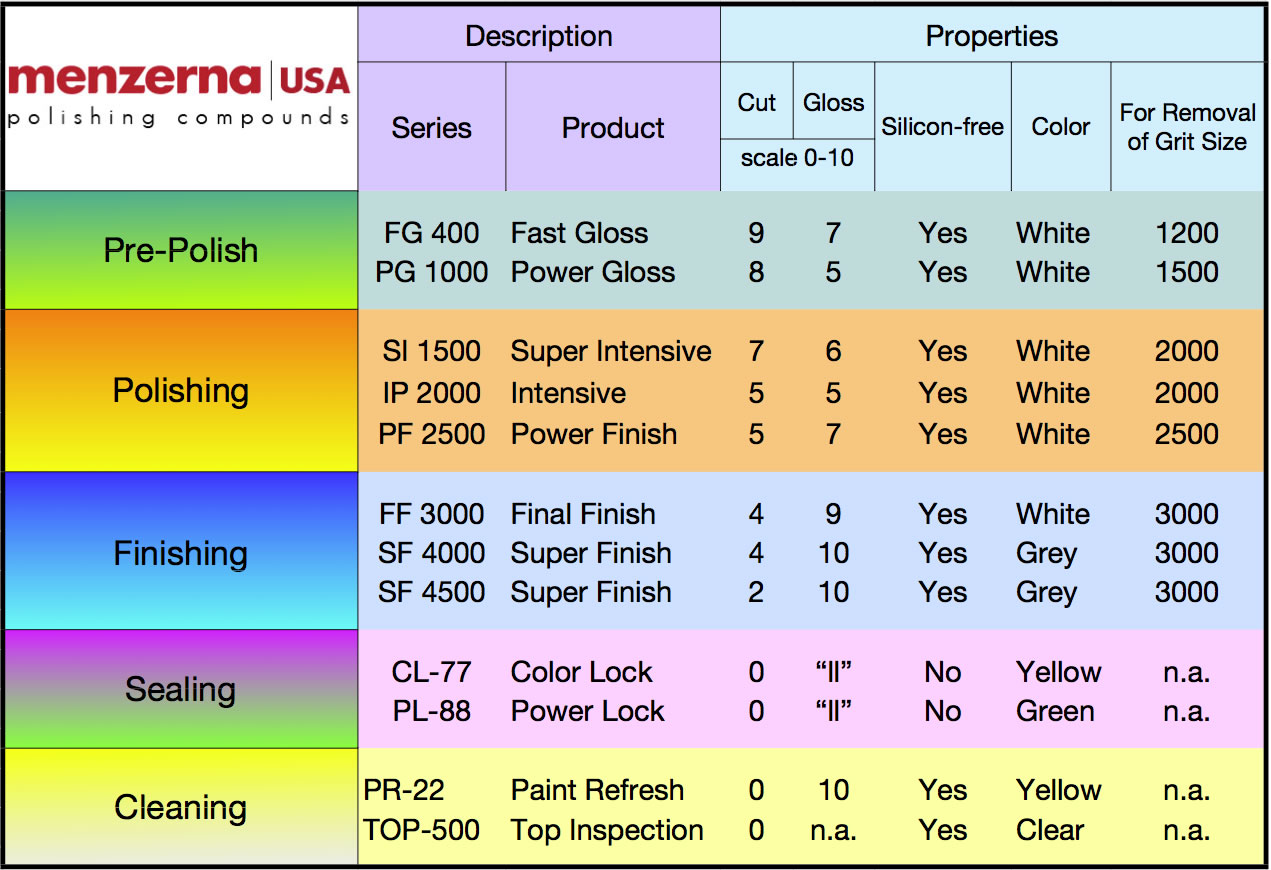

Menzerna Polishing Chart Detailed Image

The Main Difference Between Buffing And Polishing Is That Buffing Removes Scratches, Marks, And Oxidation While Polishing Creates A Glossy, Reflective Finish Using A Smoother Abrasive.

Buffing Is The Act Of Smoothing Out A Surface And Giving It A Shiny Appearance.

The Term Buffing Is A Superfinishing Process In Which There Is A Buffing Wheel (Attached With Abrasive Disc) That Is Used To Remove The Bur Or Unwanted Material From The.

It Utilizes A Rotating Wheel Or Pad,.

Related Post: