Bearing Clearance Chart

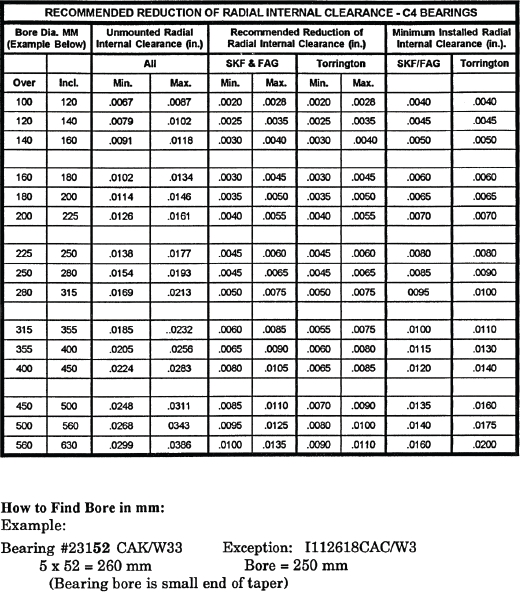

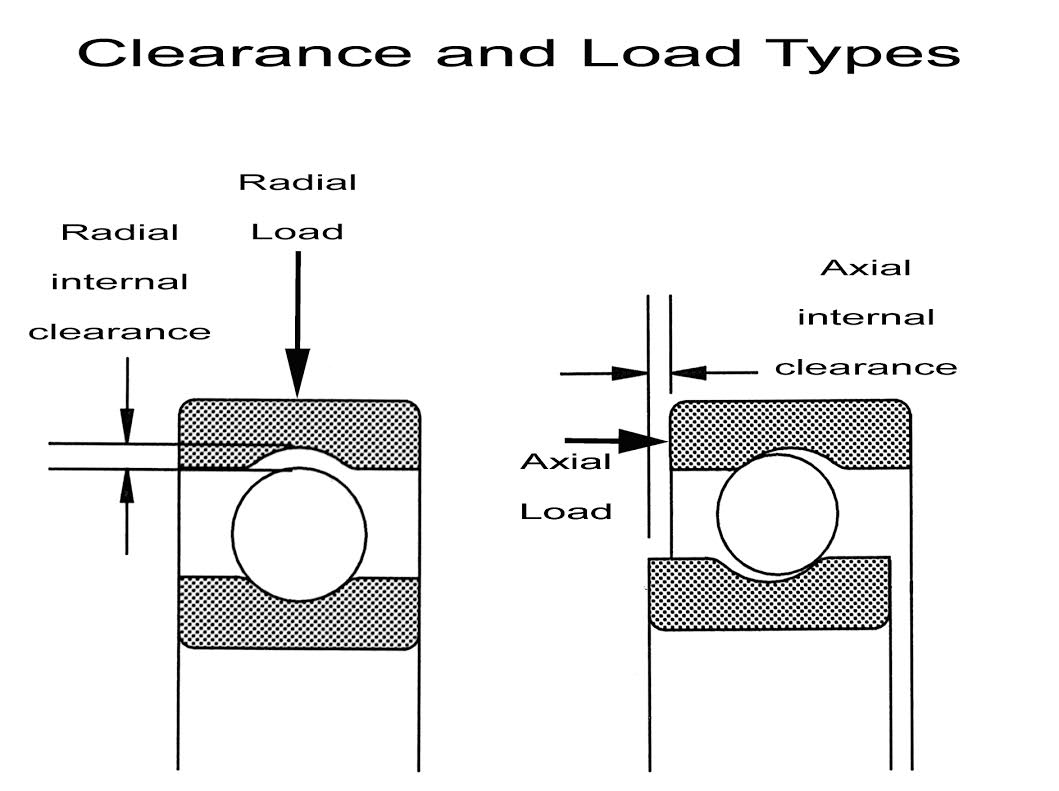

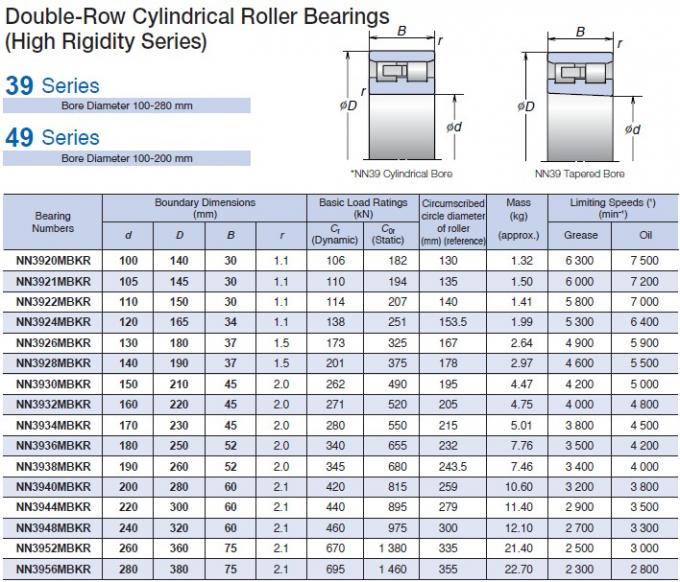

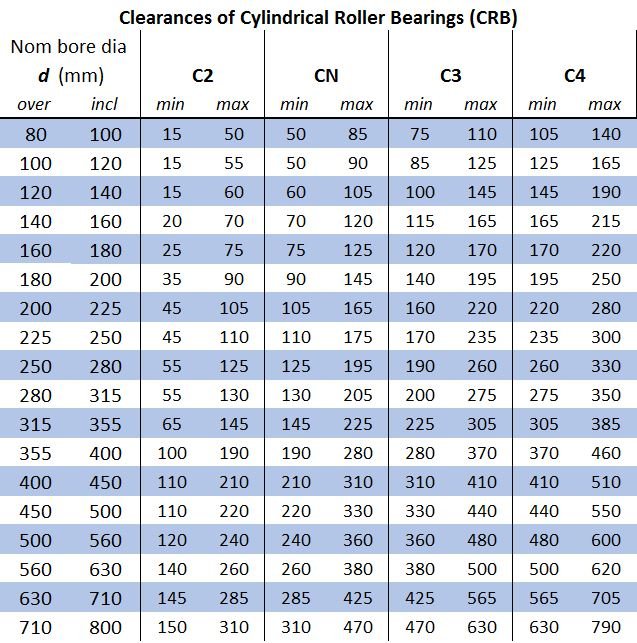

Bearing Clearance Chart - They can be known as the part of a. Ball, roller, and sleeve bearings ready to bolt in place. Get ready to discover how these engineering marvels. In this article, we’ll dive into the fascinating world of bearings, exploring 14 different types and their unique applications. There are two types of bearings: In this article, we are going to learn the basics of bearings like, definition, different parts, types, applications, maintenance tips, causes of failures, etc. With no moving parts, the plainest type of bearing. A bearing is a mechanical element that is used on applications and equipment where rotary and linear motion are required or present. A bearing is a machine element that constrains relative motion to only the desired motion and reduces friction between moving parts. It eases the movement, reduces fatigue, and improves speed and. Bearings are machine elements that allow components to move with respect to each other. It eases the movement, reduces fatigue, and improves speed and. In this article, we’ll dive into the fascinating world of bearings, exploring 14 different types and their unique applications. Support higher loads than ball bearings, but run at lower speeds. A bearing is a machine element that constrains relative motion to only the desired motion and reduces friction between moving parts. Different types of bearings are available based on our requirements. There are two types of bearings: A bearing is a mechanical part that allows linear or rotational movement and reduces friction between two objects. A bearing is a mechanical element that is used on applications and equipment where rotary and linear motion are required or present. Rolling bearings provide high precision and low friction and therefore enable high rotational speeds while reducing noise, heat, energy consumption and wear. A bearing is a machine element that constrains relative motion to only the desired motion and reduces friction between moving parts. A bearing is a mechanical part that allows linear or rotational movement and reduces friction between two objects. In other words, a bearing is a machine element that constrains relative motions and is used to reduce the friction between. In other words, a bearing is a machine element that constrains relative motions and is used to reduce the friction between moving parts. Bearings are a very small and crucial element. Bearing is employed to support, guide,. In this article, we are going to learn the basics of bearings like, definition, different parts, types, applications, maintenance tips, causes of failures,. With no moving parts, the plainest type of bearing. Ball, roller, and sleeve bearings ready to bolt in place. It is used to restrict degrees of freedom of any part. In this article, we’ll dive into the fascinating world of bearings, exploring 14 different types and their unique applications. Bearings are machine elements that allow components to move with respect. Ball, roller, and sleeve bearings ready to bolt in place. A bearing is a mechanical part that allows linear or rotational movement and reduces friction between two objects. It is used to restrict degrees of freedom of any part. Different types of bearings are available based on our requirements. It eases the movement, reduces fatigue, and improves speed and. Bearing is employed to support, guide,. In this article, we are going to learn the basics of bearings like, definition, different parts, types, applications, maintenance tips, causes of failures, etc. Support higher loads than ball bearings, but run at lower speeds. Different types of bearings are available based on our requirements. Get ready to discover how these engineering marvels. Bearing is employed to support, guide,. In this article, we are going to learn the basics of bearings like, definition, different parts, types, applications, maintenance tips, causes of failures, etc. A bearing is a mechanical element that is used on applications and equipment where rotary and linear motion are required or present. A bearing is a machine element that constrains. In this article, we are going to learn the basics of bearings like, definition, different parts, types, applications, maintenance tips, causes of failures, etc. Get ready to discover how these engineering marvels. Bearings are a very small and crucial element. They can be known as the part of a. There are two types of bearings: It is used to restrict degrees of freedom of any part. Get ready to discover how these engineering marvels. In this article, we’ll dive into the fascinating world of bearings, exploring 14 different types and their unique applications. Ball, roller, and sleeve bearings ready to bolt in place. Support higher loads than ball bearings, but run at lower speeds. In this article, we’ll dive into the fascinating world of bearings, exploring 14 different types and their unique applications. Bearings are a very small and crucial element. Support higher loads than ball bearings, but run at lower speeds. Get ready to discover how these engineering marvels. There are two types of bearings: A bearing is a mechanical part that allows linear or rotational movement and reduces friction between two objects. A bearing is a machine element that constrains relative motion to only the desired motion and reduces friction between moving parts. With no moving parts, the plainest type of bearing. Bearing is employed to support, guide,. Bearings are machine elements that allow. Bearings are a very small and crucial element. They can be known as the part of a. It eases the movement, reduces fatigue, and improves speed and. With no moving parts, the plainest type of bearing. It is used to restrict degrees of freedom of any part. Ball, roller, and sleeve bearings ready to bolt in place. A bearing is a machine element that constrains relative motion to only the desired motion and reduces friction between moving parts. A bearing is a mechanical element that is used on applications and equipment where rotary and linear motion are required or present. In this article, we are going to learn the basics of bearings like, definition, different parts, types, applications, maintenance tips, causes of failures, etc. Bearing is employed to support, guide,. In this article, we’ll dive into the fascinating world of bearings, exploring 14 different types and their unique applications. Get ready to discover how these engineering marvels. A bearing is a mechanical part that allows linear or rotational movement and reduces friction between two objects. Bearings are machine elements that allow components to move with respect to each other. In other words, a bearing is a machine element that constrains relative motions and is used to reduce the friction between moving parts.BEARING CLEARANCE (C1,C2,CN,C3,C4,C5)

Technology FASTBEARINGS.,LTD.

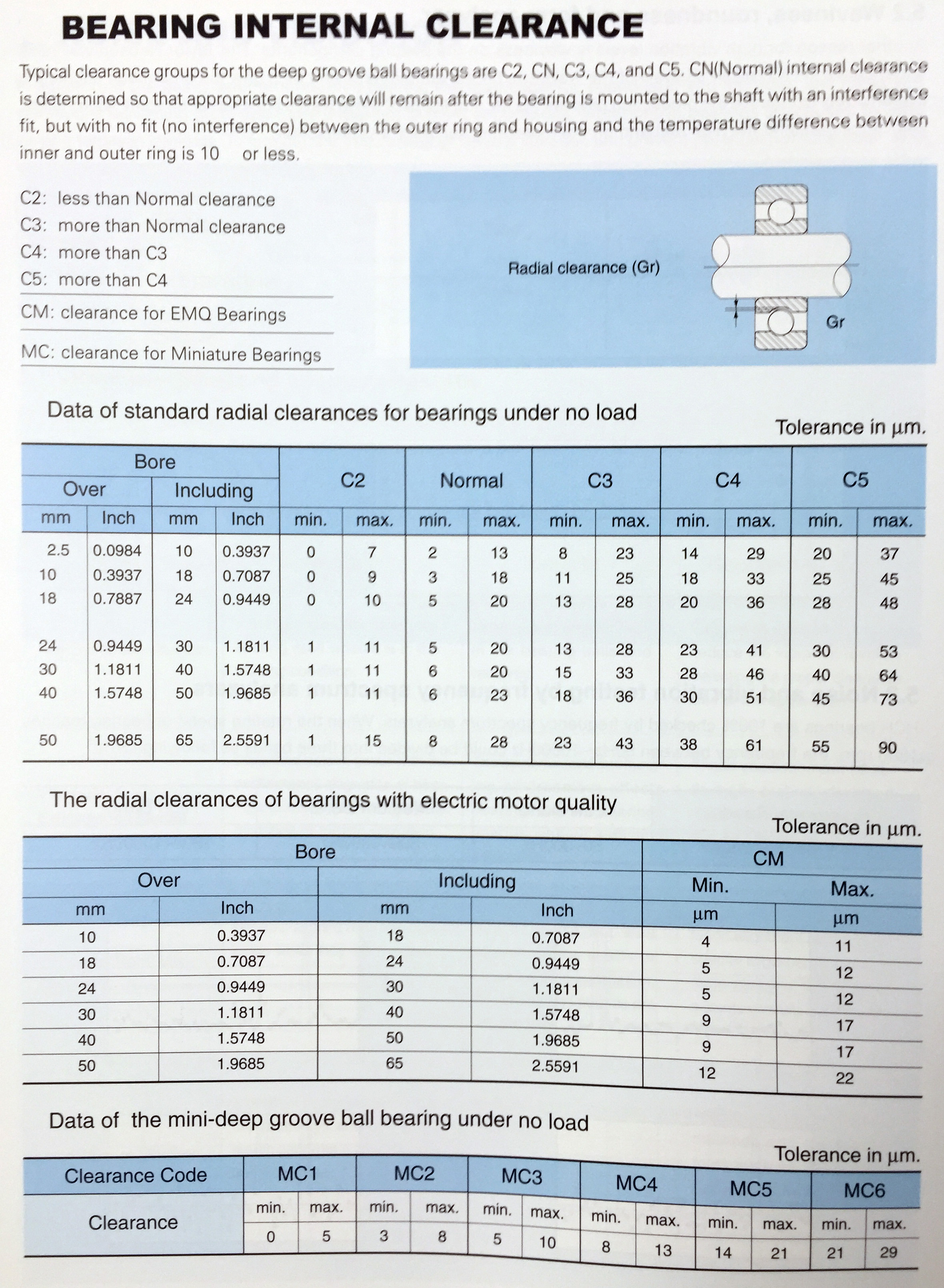

BEARING CLEARANCE (C1,C2,CN,C3,C4,C5)

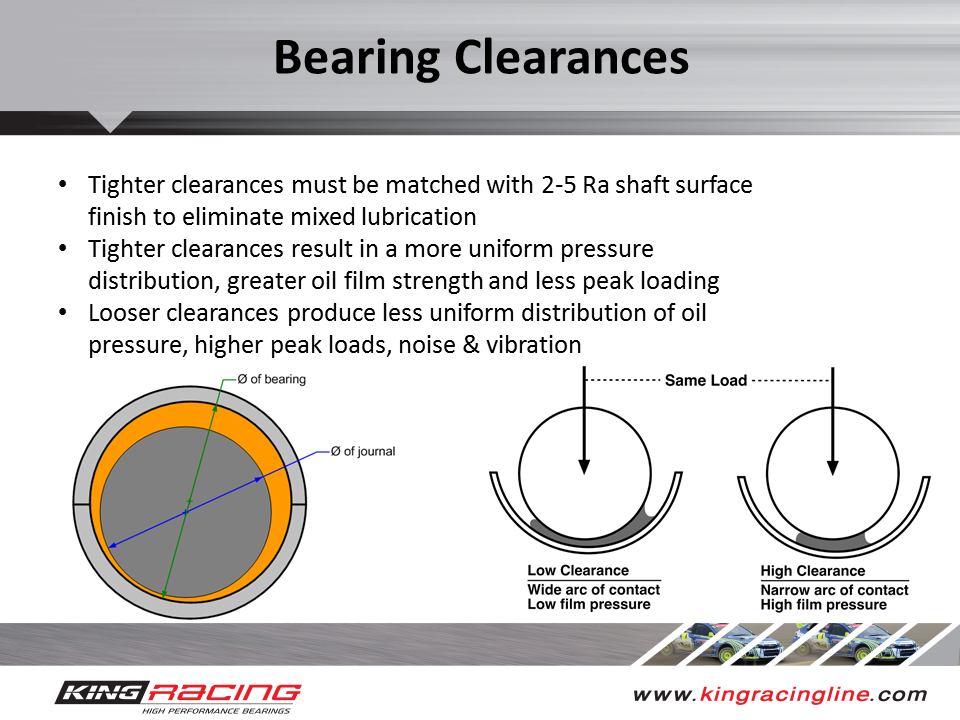

UNDERSTANDING OIL CLEARANCES IN ENGINE BEARINGS Engine Builder Magazine

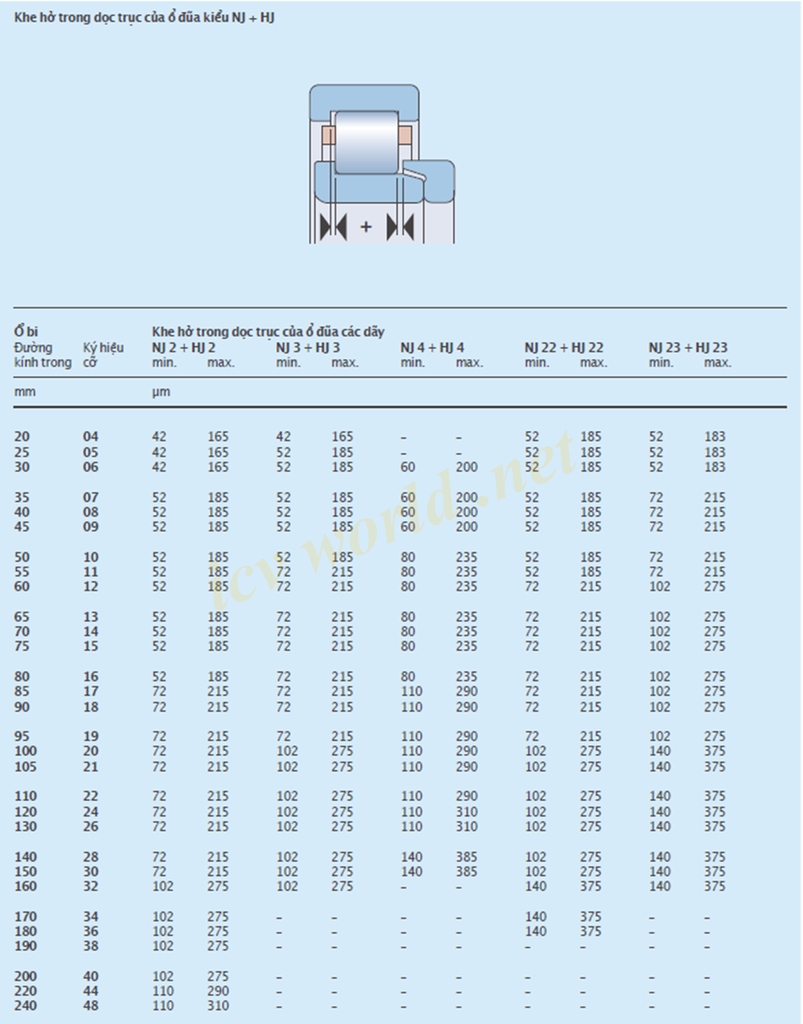

Journal inspection, dryer bearing fit and internal clearance

Levels of Precision—Protect Your Bearings with Proper Clearance Fits and Preloads

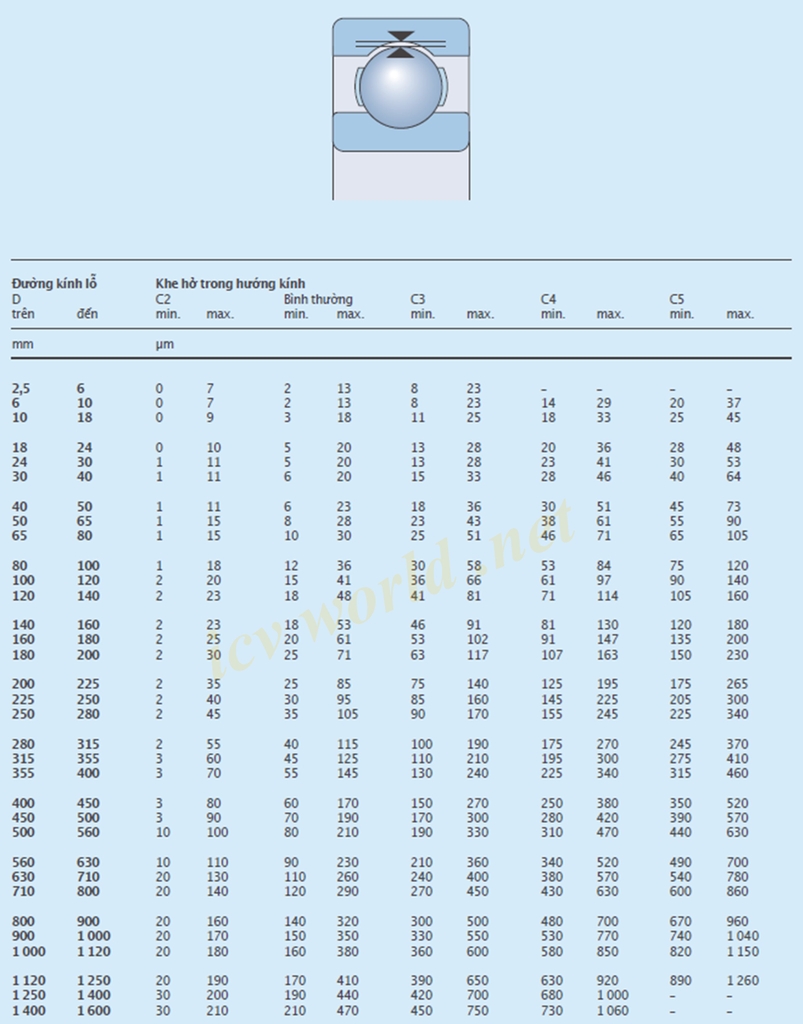

C3 Bearing Clearance Chart A Visual Reference of Charts Chart Master

C3 Bearing Clearance Chart A Visual Reference of Charts Chart Master

Bearing Internal Clearance — Malloy Wind

White Metal Bearing Clearance Chart A Visual Reference of Charts Chart Master

Rolling Bearings Provide High Precision And Low Friction And Therefore Enable High Rotational Speeds While Reducing Noise, Heat, Energy Consumption And Wear.

Different Types Of Bearings Are Available Based On Our Requirements.

Support Higher Loads Than Ball Bearings, But Run At Lower Speeds.

There Are Two Types Of Bearings:

Related Post: